Page 224 - Praxair - Specialty Gases and Equipment Reference Guide

P. 224

Laser Gases and Support

Services

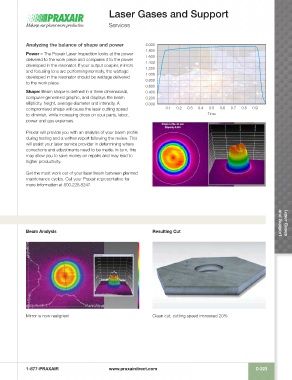

Analyzing the balance of shape and power 2.000

1.800

Power – The Praxair Laser Inspection looks at the power 1.600

delivered to the work piece and compares it to the power 1.400

developed in the resonator. If your output coupler, mirrors 1.200

and focusing lens are performing normally, the wattage 1.000

developed in the resonator should be wattage delivered 0.800

to the work piece.

0.600

Shape: Beam shape is defined in a three dimensional, 0.400

computer-generated graphic, and displays the beam 0.200

ellipticity, height, average diameter and intensity. A 0.000

compromised shape will cause the laser cutting speed 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9

to diminish, while increasing dross on your parts, labor, Time

power and gas expenses.

Praxair will provide you with an analysis of your beam profile

during testing and a written report following the review. This

will assist your laser service provider in determining where

corrections and adjustments need to be made. In turn, this

may allow you to save money on repairs and may lead to

higher productivity.

Get the most work out of your laser beam between planned

maintenance cycles. Call your Praxair representative for

more information at 800.225.8247.

Beam Analysis Resulting Cut and Support Laser Gases

Mirror is now realigned Clean cut, cutting speed increased 20%

1-877-PRAXAIR www.praxairdirect.com D•223