Page 223 - Praxair - Specialty Gases and Equipment Reference Guide

P. 223

Laser Gases and Support

Services

Improve Laser Efficiency and Performance

with Praxair’s Laser Inspection

It’s easy to see and determine if your mechanical metal We also review your laser gas delivery system, which

cutting tools are sharp, however, your laser is more has proven to reduce gas expense and extend laser com-

challenging since the cutting beam is invisible. But how ponent service life. This combination provides a recipe of

do you know if your laser is as effective as it could be? continuous performance, while minimizing laser downtime.

Praxair’s Laser Inspection can help.

The inspection is non-invasive and only takes 20-60

With Praxair’s Laser Inspection, several output aspects of minutes. Once the testing is complete, you’ll be able

your laser will be examined, such as beam power at the to view a computer-generated report that will give you

work piece versus the power produced in the resonator and an instantaneous diagnosis of the beam and a clear

beam shape. explanation of what part of the beam is out of spec.

Old Beam Checking Methods Praxair’s Laser Inspection

Tape Shot Praxair’s Laser Inspection

n 2D method lacks spatial beam profile n 3D beam scan with spatial beam profile

n Fails to define energy distribution n Defines 3D color energy distribution

n Ignores beam fluctuations over time

n Reports beam fluctuations over time

Acrylic Mode Burns n Reports power at the work piece

n 3D method lacks spatial beam profile n Accurate readings of diameter and ellipticity

n Fails to define energy distribution

n Ignores beam fluctuations over time n Provides ellipticity ratios and measurements

Output Wattage

n Resonator power reported only in the power source

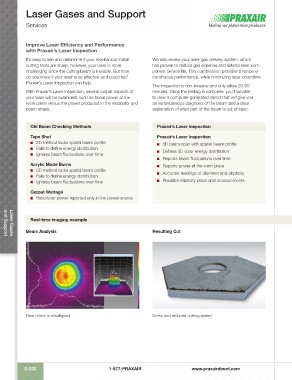

Real-time imaging example

Beam Analysis Resulting Cut

and Support

Laser Gases

Rear mirror is misaligned Dross and reduced cutting speed

D•222 1-877-PRAXAIR www.praxairdirect.com