Page 300 - Praxair - Specialty Gases and Equipment Reference Guide

P. 300

Gas Delivery Systems

Control Panels

Typical Applications

Used on corrosive and high purity gases for ultimate safety in

cylinder changeouts. Panels can be located in gas cabinets,

please see page E •305 for further details.

Features and Benefits

n Brushed Stainless Steel n Mountable to Any Suitable

Panel Surface

Easy installation

n Wall Mounted to Protect the

Regulator n Metal-to-Metal Diaphragm

n Labeled for Gas Service Seal

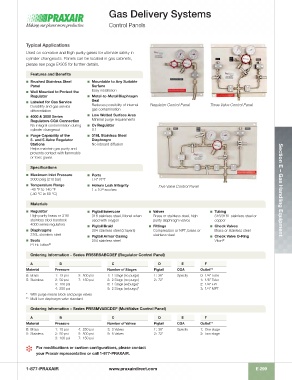

Durability and gas service Reduces possibility of internal Regulator Control Panel Three Valve Control Panel

differentiation gas contamination

n 4000 & 3000 Series n Low Wetted Surface Area

Regulators CGA Connection Minimal purge requirements

No integral contamination during n Cv Regulator

cylinder changeout 0.1

n Purge Capability of the n 316L Stainless Steel

3- and 5-Valve Regulator Diaphragm

Stations No inboard diffusion

Helps maintain gas purity and

prevents contact with flammable

or toxic gases

Specifications

n Maximum Inlet Pressure n Ports

3000 psig (210 bar) 1/4" FPT

n Temperature Range n Helium Leak Integrity Five Valve Control Panel

-40 °F to 140 °F 1 x 10 scc/sec Section E – Gas Handling Equipment

-9

(-40 °C to 60 °C)

Materials

n Regulator n Pigtail Innercore n Valves n Tubing

High purity brass or 316L 316 stainless steel, Monel when Brass or stainless steel, high 316/316L stainless steel or

stainless steel barstock used with oxygen purity diaphragm valves copper

4000 series regulators

n Pigtail Braid n Fittings n Check Valves

n Diaphragms 304 stainless steel (2 layers) Compression or NPT, brass or Brass or stainless steel

316L stainless steel stainless steel

n Pigtail Armor Casing n Check Valve O-Ring

n Seats 304 stainless steel Viton ®

PTFE Teflon ®

Ordering Information – Series PRS5RSABCDEF (Regulator Control Panel)

A B C D E F

Material Pressure Number of Stages Pigtail CGA Outlet**

B: Brass 1: 15 psi 5: 500 psi 1: 1 Stage (no purge) 1: 36" Specify 0: 1/4" Tube

S: Stainless 2: 50 psi 7: 150 psi 2: 2 Stage (no purge) 2: 72" 1: 1/8" Tube

3: 100 psi 8: 1 Stage (w/purge)* 2: 1/4" FPT

4: 250 psi 9: 2 Stage (w/purge)* 3: 1/4" MPT

* With purge means block and purge valves

** Multi turn diaphragm valve standard

Ordering Information – Series PRS5MVABCDEF (MultiValve Control Panel)

A B C D E F

Material Pressure Number of Valves Pigtail CGA Outlet**

B: Brass 1: 15 psi 4: 250 psi 3: 3 Valves 1: 36" Specify 1: One stage

S: Stainless 2: 50 psi 5: 500 psi 5: 5 Valves 2: 72" 2: Two stage

3: 100 psi 7: 150 psi

i For modifications or custom configurations, please contact

your Praxair representative or call 1-877-PRAXAIR.

1-877-PRAXAIR www.praxairdirect.com E•299