Page 302 - Praxair - Specialty Gases and Equipment Reference Guide

P. 302

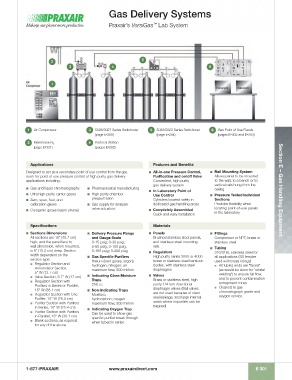

Gas Delivery Systems

Praxair’s VersiGas Lab System

™

5

2

3 4 6

1

1 Air Compressor 3 5026/5027 Series Switchover 5 5022/5023 Series Switchover 6 Gas Point of Use Panels

(page E •285) (page E •284) (pages E •302 and E •303)

2 Membrane N 2 4 Protocol Station

(page E •331) (pages E •282)

Applications Features and Benefits

Designed to act as a secondary point of use control from the gas n All-in-one Pressure Control, n Rail Mounting System

room for point of use pressure control of high purity gas delivery Purification and on/off Valve Allows panel to be mounted

applications including: Convenient, high purity to the wall, to a bench or to

gas delivery system vertical rails hung from the

n Gas and liquid chromatography n Pharmaceutical manufacturing ceiling

n In Laboratory Point of Section E – Gas Handling Equipment

n Ultra high purity carrier gases n High purity chamber Use Control n Pressure Tested Individual

n Zero, span, fuel, and pressurization Cylinders located safely in Sections

calibration gases n Gas supply for analyzer dedicated gas handling areas Provides flexibility when

n Cryogenic gases (vapor phase) valve actuation. n Completely Assembled locating point-of-use panels

Quick and easy installation in the laboratory

Specifications Materials

n Sections Dimensions n Delivery Pressure Range n Panels n Fittings

All sections are 18" (45.7 cm) and Gauge Scale Brushed stainless steel panels, Compressor or NPT, brass or

high, and the panel face to 0-15 psig; 0-30 psig; and stainless steel mounting stainless steel

wall dimension, when mounted, 0-60 psig; 0-100 psig, rails n Tubing

is 6" (15.2 cm) deep. Section 0-160 psig; 0-200 psig n Regulators 316/316L stainless steel for

width dependent on the n Gas Specific Purifiers High purity series 3000 or 4000 all applications (SS ferrules

section type: Helium (inert gases, argon); brass or stainless steel barstock used with brass fittings)

n Regulator Section and hydrogen; nitrogen; air bodies, with stainless steel n All tubing ends are “faced”

Annunciator Section, maximum flow, 500 ml/min diaphragms (as would be done for “orbital

5" W (12.7 cm) welding”) to ensure full flow,

n Valve Section, 6.7" W (17 cm) n Indicating Glass Moisture n Valves and to prevent contamination

n Regulator Section with Traps Brass or stainless steel, high entrapment zones

Purifiers in Series or Parallel, 250 cc purity 1/4 turn directional n Cleaned to gas

15" W (38.1 cm) n Non-Indicating Traps diaphragm valves (Ball valves chromatograph grade and

n Regulator Section with One Moisture; are not used because of stem oxygen service

Purifier, 10" W (25.4 cm) hydrocarbon; oxygen seal leakage, and large internal

n Purifier Section with Purifiers maximum flow, 500 ml/min areas where impurities can be

in Series, 10" W (25.4 cm) n Indicating Oxygen Trap trapped)

n Purifier Section with Purifiers Can be used to show gas

in Parallel, 15" W (38.1 cm) specific purifier break through

n Blank sections, as required when tubed in series

for any of the above

1-877-PRAXAIR www.praxairdirect.com E•301